Jobghost.blogspot.com explains most important topics in Civil engineering for the GATE-2016 examination. Here the “TRANSPORTATION ENGINEERING-Highway Materials and testing” topics are explained. The important test and test procedures in civil engineering are mentioned. Each and every word given below is important for all your civil engineering competitive examinations. And also the GATE-2016 practice sets, Example problems, previous year Question papers are available in jobghost.blogspot.com.

Subgrade is the

foundation or earth fill which directly bear the loads from the pavement. This

layer lies just below the pavement. It should provide adequate support to the pavement.

And it should not get affected due to adverse climate and loading conditions.

Modulus of Sub-grade reaction (K):

It is the pressure

sustained per unit deformation of subgrade at specified deformation or pressure

level, in plate bearing test. So it is the behavior of subgrade for the

specified pressure. The modulus of subgrade reaction found out by using

subgrade reaction test. Standard dimensions of the tests given below.

Standard plate size for test = 75 cm

Standard Settlement = 0.125 cm

Standard Pressure = 0.7 kg/ cm2

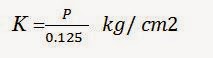

Formula for K:

There are two methods

available to find the modulus of sub-grade reaction.

i.

In this

method the standard settlement value taken as constant and the load causes the

standard settlement is taken as test pressure “p”. Then the sub-grade reaction value is..

ii.

In this

method the standard pressure is taken as constant and settlement due to the

standard load is taken as the test settlement value. Then the subgrade reaction

value is ..

P -----> Pressure in kg/

cm2

Plate Correction for

Different plate used for test:

The subgrade modulation

test always performed with 75cm diameter standard plate. But sometimes due to

the site conditions various size diameters are used. To rectify the error due

to change in diameter, following formula is used.

k1-----> K @ Smaller plate

a1---->

Radius of smaller plate

K ----> K for

Standard plate

a ----> Radius of standard

plate

2.

CBR

Test:

This test is used for

evaluating the stability of soil subgrade and other flexible pavements.

Flexible pavement thickness is determined based on this test. Usually this test

is conducted in the laboratory and also in the field.

It is an arbitrary

strength test and hence cannot be used to evaluate the soil properties like

cohesion or internal friction or shearing resistance. Material passing 20 mm

sieve is only used. The presence of coarse grained particles would result in

poor results in the test. The test is meant for soil but it is also carried out

on sub base and granular base course materials.

The test apparatus

consists of Cylindrical mould of diameter 150 mm , Base plate , Cylindrical

plunger of 50 mm diameter and compression testing machine.

Test procedure:

Test specimen is kept

in a mould and it is subjected to four days soaking. Then the load is applied

in the cylindrical plunger of 5cm diameter so that the penetration rate is 1.25

mm/minute. The load penetration curve is plotted for all penetration values.

The test load for 2.5 mm and 5 mm penetration are recorded.

The CBR value found out with the following two formulas.

The CBR value found out with the following two formulas.

CBR value for 2.5 mm

penetration

CBR value for 5.0 mm

penetration

* Standard load

@ 2.5 mm penetration = 1370

* Standard load @ 5 mm

penetration = 2055

* Higher of Two value taken as CBR value.

* Normally CBR (2.5) value is always greater than the CBR (5.0).

i.e[CBR(2.5) > CBR (5)]

3. Marshal

Stability test for Bitumen:

Marshall Stability test

is to determine the stability of bitumen at 600 standard test temperatures.

Stability is defined as the load carrying capacity of compacted specimen at

test temperature. So this test is conducted to find the load carrying capacity

of paving bitumen at high temperature. Tis test is applicable to hot-mix paving

mixture containing 2.5cm size aggregates.

It is the type of

Unconfined compressive strength test , in which a cylindrical specimen 10 cm

diameter and 6.3 cm height is compressed radially at a constant rate of strain

of 5 cm/minute.

Standard temperature 60oC

the corresponding load carrying capacity of specimen is called marshal

stability value and the deformation at failure in units of 0.25 mm is recorded

as Marshal Flow value. Prior to stability density voids analysis is carried out

on the test specimens. The optimum binder content for the aggregate mixture and

anticipated traffic conditions is a compromise value which meets specified

requirements for stability flow value and voids content.

Voids In Mineral

Aggregate:

Voids In Mineral Aggregate(VMA) = Va + Vb

Volume of air voids

Volume of bitumen

Theoretical Specific Gravity

Gm= Measured specific gravity

Voids

Filled With Bitumen:

Here…

ca=Coarse aggregate

|

fa=fine aggregate

|

fill

=filler

|

bit =bitumen

|

Gt ----> Theoretical Specific

Gravity

Gm ----> Measured Specific Gravity

W ----> Weight

G ----> Specific Gravity

Va ---->Volume of

air voids

No comments:

Post a Comment